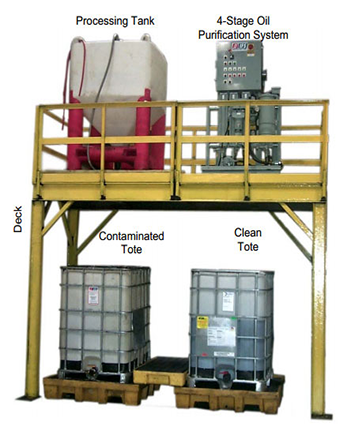

Complete 4-Stage Oil Purification System – Hydraulic Oil E.F.S.-14022-C4SOPS

This System will process a 320 gallon tote in 1 to 3 days

depending on the level of contamination.

The 4-Stage Oil Purification System is designed to filter/purify 300 gallon of hydraulic oil in 24 to 48 hours. It is based on the concept of multiple passes through multiple filters to remove water, solids, and micro solids. The 4-Stage Oil Purification System requires a 480 volt, 3 phase power supply. This system includes processing tank, deck, (1) clean tote, and (2) contaminated totes.

Industrial Fluid Systems – Oil Purification System – Complete 4 Stage – E.F.S.-14022-C4SOPS PDF

System Components

- Clean Oil Tote

- Contaminated Oil Tote

- 4-Stage Oil Purification System

- Processing Tank—320 Gal.

- Steel Platform

- Drip Pans

- Staircase (Not Shown)

Standard Features

- 1.25 GPM Process Flow Rate

- 5kW Heater

- Oil Pump

- Electrical Controls, w/ “On” indicator, alarm lights and phase monitor

- 480V—3Ph—60Hz Power

- Pressure Gauge

- Suction Filter w/ 60 Micron Element

- Four NTZ Filters w/ 2-5 Micron

- Drip Pan w/ Fork Lift Pockets

- PLC Convenience Port

- Contaminated Oil Tote

- Clean Oil Tote

- One Year Warranty

- Operational & Maintenance Manual w/ Spare Parts List