Fluid Recycling Equipment Rebuilding, Refurbishing

Rebuilding or remanufacturing equipment can save 50% to 60% of the cost for a new machine. IFS rebuilds centrifuges and vacuum dehydrators to “like new, or better” condition. We will updated or replace controls including sensors and displays. Options not available when the equipment was first manufactured can be added. New manuals and drawings are provided as part of the remanufacturing process.

Centrifuges

Over time, even centrifuges that have been moderately to well maintained begin to show signs of wear. Paint gets scratched, dirt builds up and controls become outdated. However, the most expensive component, the centrifuge it-self, lasts long after these physical signs of wear appear.

That is why at IFS we offer a centrifuge module rebuild service. With over 10 years of experience building, servicing and repairing Alfa Laval centrifuge systems, we have the expertise necessary to take your old machine and make it look and work like new for a fraction of the cost of a new system.

Ultra Vac (UV10) Rebuild

Parker PVS600 Rebuild

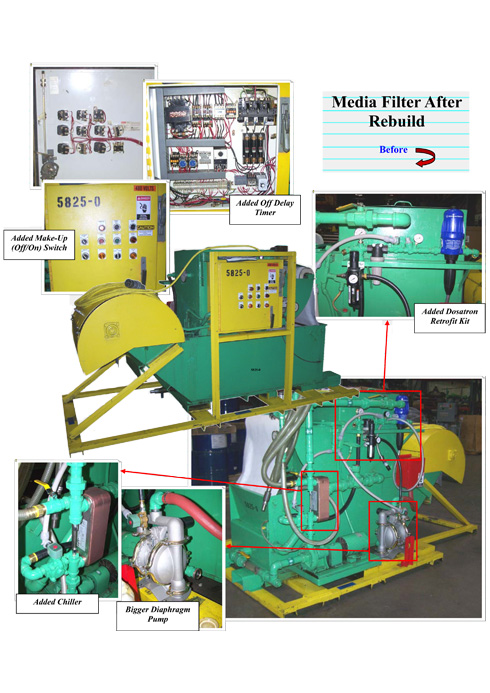

Media Filter Rebuild

Engineered Solutions

At IFS our strength is in our years of experience designing and manufacturing the right solution for our customer’s application. Our engineers can engineer equipment using standard, high quality components to meet your specific needs.

Experience

Our professionals have over 20 years of experience in analyzing and implementing fluid cost savings projects