HBMS Stamping Fluid Mixers improve service and control costs in a competitive market

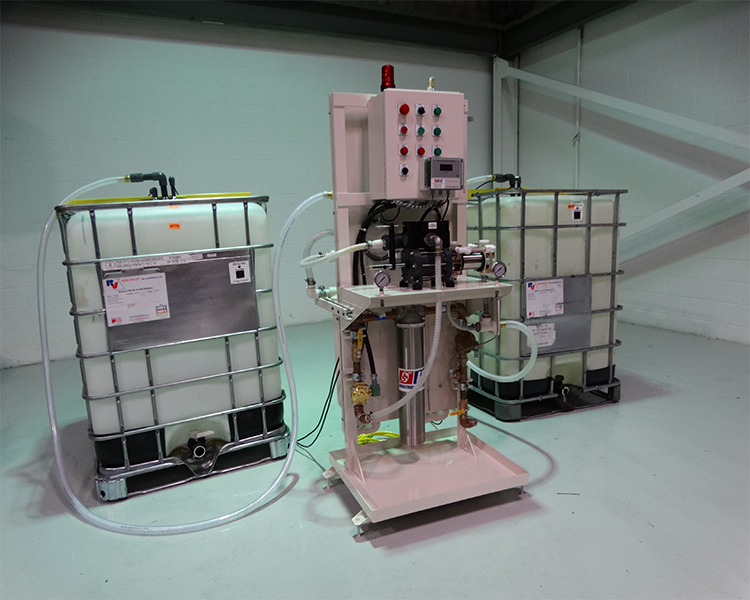

This system was engineered and built for a chemical distributor looking to provide their customer with a cost effective premixed product. The product was being mixed in the US and shipped to Canada on a weekly basis. Shipping cost and the ability to get product on a timely basis created problems Cold weather shipping restrictions increased the cost by 25%.

The decision was made to mix the product at their facility in Toronto, Canada. The goal was to find a cost effective mixing system that was automated and would require minimum operator experience or involvement.

The HBMS positive displacement mixer is reliable and is easily adjusted. The addition of an inline electronic refractometer insured the customer and the distributor that the product was being mixed at the proper concentration. Optional static mixing chambers insured that the product was completely mixed.

Working with the chemical supplier and the customer we were able to come up with a cost effective solution resulting in a win-win situation for everyone.

IFS has built systems for over 20 years for applications including:

- Coolant Recycling

- Cutting Oil Recycling

- Waste Water Processing

- Wash Water Recycling

- Oil Purification Systems

- Waste Oil Processing

Our professionals can help you decide what type of system will work best for your application. Contact us today for more information.

System Requirements

- Automatically mix totes of stamping fluid

- Adjust concentration based on customers requirements

- Monitor concentration electronically

- Monitor chemical supply and stop mixing when low

- Operate on 120 VAC

- Installation assistance and onsite training

- Meet UL & CEC specs.

Equipment Specifications

- HBMS Positive Displacement Mixer

- 25 GPM mix pump

- 120 VAC controls

- Batch/Continuous mixing

- Electronic Refractometer

- Air/Water sensors

- Mixed fluid sensors

- chamber Static mixing

- CEC & UL rated components

- Mix Water System w/Filter

- Complete Documentation with Spare Parts List

- Installation Assistance and on site training

- One Year Warranty on the System

- Runoff on Customer Supplied Fluid