Gear Lube Oil Systems

Starting a dredger gearbox when the oil is cold puts tremendous strain on gears, bearings and the entire drive package. Running the gearbox with hot or dirty oil is just as bad. A lube conditioning system was the key to extending their life. Temperatures in the Southern United States have been hitting new lows and highs for several years. The cold temperatures were causing bearing failures and excessive wear on gearboxes in offshore dredgers. The solution to the problem was to heat the gear lube for several hours before starting the dredger so oil flowed freely and bearings were warm. High temperatures were also an issue and so the system was designed to include an air cooled heat exchanger to help cool the oil once it reached 130F.

Prior to building this system IFS worked with the gearbox manufacturer to establish the flow rate, temperature requirements and oil quality required to maximize performance and gearbox life.

IFS has 20 years of experience building turnkey systems for:

- Coolant Recycling

- Cutting Oil Recycling

- Waste Water Processing

- Wash Water Recycling

- Oil Purification Systems

- Waste Oil Processing

Contact us today for more information.

System Requirements

- Heat gear lube oil to 110F for startup

- Cool gear lube oil with air cooled heat exchanger when temperature exceeds 130 F

- Filter lube oil once it reaches 100F to extend oil and bearing life

- Engineer lube conditioning system controls to operate system from the bridge

- Provide engineering and technical support to dredger engineer.

- Provide installation and startup assistance on dredger as required

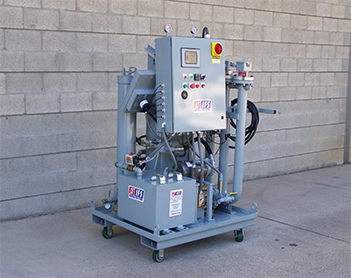

Equipment Provided

- GLCS-8G-12KW-15G Gearbox Lube Conditioning System

- 8 GPM Lube filter/heater pump

- 12kW Heater w/PID controller

- Duplex oil filters

- 15 GPM Cooling Pump

- Control Panel w/ interface

- Sample Ports

- Sample Ports

- Air cooled heat exchanger

- Installation and startup assistance on dredger

- Operational & Maintenance Manual w/ Spare Parts List

Gerdau Custom UV-10

The UV-10 vacuum dehydration unit is capable of removing water from most lubricating, EHC and hydraulic fluids. It is designed for 1,000-1,500 gallon systems. This machine will process fluid at a rate of 600 gallons per hour and is capable of reducing water levels to less than 25 ppm. Options and custom modifications are available.

Standard Features

- 600 GPH Process Flow Rate

- 36kW Heater w/Programmable Temperature Controller

- Dry Seal Vacuum Pump w/ Oil Sump

- Electrical Controls w/ “On” indicator, alarm lights and phase monitor

- 440V-3Ph-60Hz Power

- Adjustable Flow Contro

- W40” x L60” x H74”

- 1,400 lbs / 635 kg

- Sample Ports

- Pressure Gauge

- Non-Re-settable Hour Meter

- Parker Filter Assembly

- Parker Filter Element

- 25’ Electrical Cord

- One Year Warranty

- Operational & Maintenance Manual w/ Spare Parts List

Safety Features

- High Temp Shutdown Circuit

- High Oil Level Shutdown

- High Condensate Tank Shutdown

Standard Options

- Fork Lift Pockets

- Inlet & Outlet Hoses

- PLC Control Screen

- Feed Shutoff Valve

- Flow Meter

- Auto Condensate Drain

Mobile Micro Filtration Oil Purification System

The Mobile Micro Filtration Oil Purification System is designed to keep your equipment running at maximum efficiency. Contaminated oil destroys bearings, seals, pumps and servo valves causing premature wear, down time and high maintenance costs. The Micro Filter removes solids, micro solids and small amounts of water extending the life of the oil and the equipment. The system runs on 120 volt, 15 amp power. Industrial Fluid Systems custom build a system to meet your requirements.

Industrial Fluid Systems – Mobile Micro Filtration Oil Purification System – PDF

Typical applications

- Hydraulic/Lube Systems 25 to 350 Gallons

- Gear Boxes

- CNC Machines

- Stamping Presses

- Servo Controlled Sys.

- Batch Recycling

- High Speed Spindle Oil

- Lube Oil

- Hydraulic Oil

- Transmission Fluid

Equipment Specifications

- 1.1 GPM/ 4.1 L/M Process Flow Rate

- 1.2 kW Heater w/Temperature Gauge

- Electrical Control w/ “On” & “Off” Push Buttons

- Power Requirement: 120V–15 Amps

- 2, 5 or 15 Micron Elements

- High Pressure Alarm

- High Temperature Alarm

- 10ft. Electrical Cord

- 10ft. Inlet & Outlet Hoses

Optional Features

- Optional Features

- Remote Level Sensors

- Particle Counter

- Moisture Sensor