Recycling Processes for a Variety of Fluid Types and Applications

We have worked on recycling projects for a variety of fluid types and metalworking applications. Here are some of the most common fluids and the typical recycling process for each.

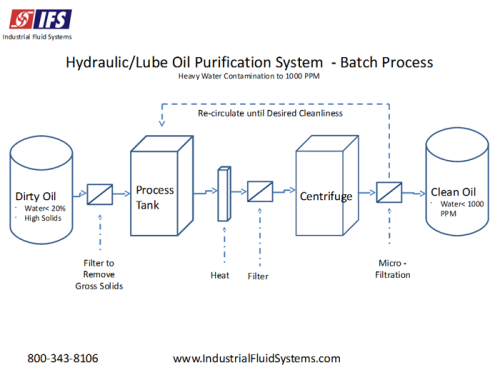

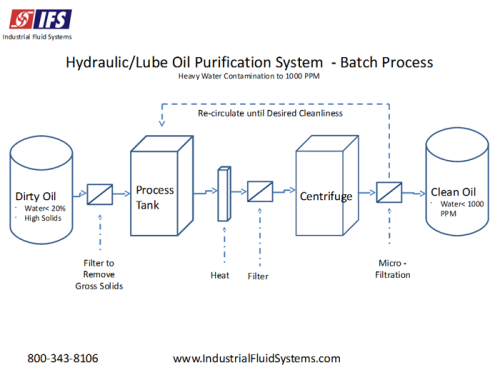

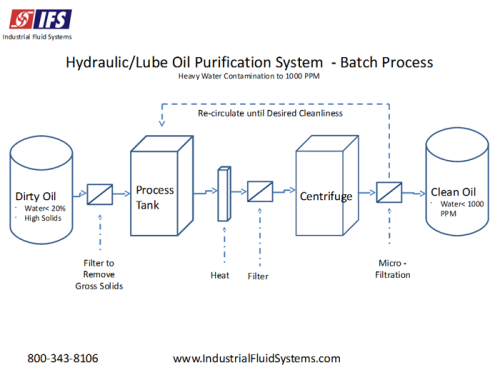

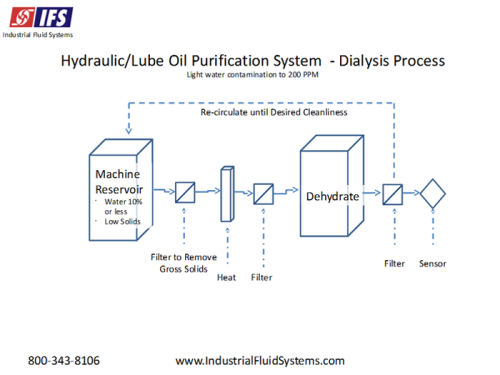

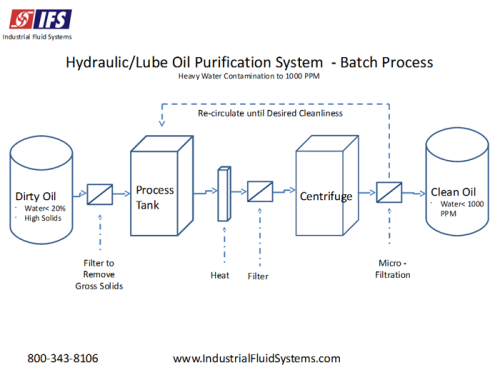

Hydraulic Oil/Lube Oil solids are the most common type of contamination and are usually removed with filters. When water is the major contaminate centrifuges and vacuum dehydrators are typically the best solution. The reclamation process is chosen based on the amount of water contamination present, the level of dryness required, and if there is any particulate contamination.

Mouseover to View Diagrams

-

Heavy Water Contamination down to 1000 PPM – Batch Process

-

Heavy Water Contamination down to 100 PPM – Batch Process

-

Light Water Contamination down to 200 PPM – Batch Process

-

Light Water Contamination down to 200 PPM – Dialysis/Machine Side Process

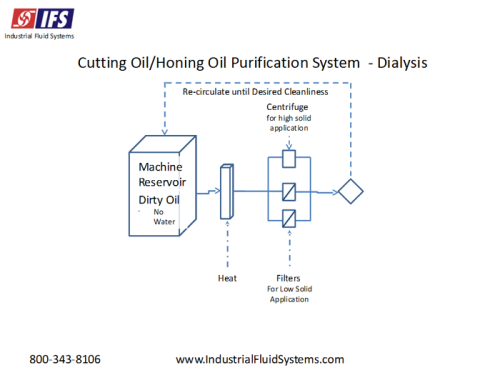

Cutting Oil/Honing Oil

Solid contaminates are the major area of

concern for these

oils. The processes used vary based on the concentration of contaminates. We can set

upbatch processor dialysis/continuous processes to

recycle these fluids depending on

the client’s needs.

recycle these fluids depending on

the client’s needs.

-

Low Solids

Filtration is the most common method where the level of solids is low. For small metallic particles, a magnetic separator can be used effectively. Solids retaining centrifuges are also an excellent choice when cost effective.

-

High Solids

When there is a high level of solids in the fluid, self-cleaning or indexing filters are typically used. Self-cleaning centrifuges are also an effective way to remove solids from these fluids

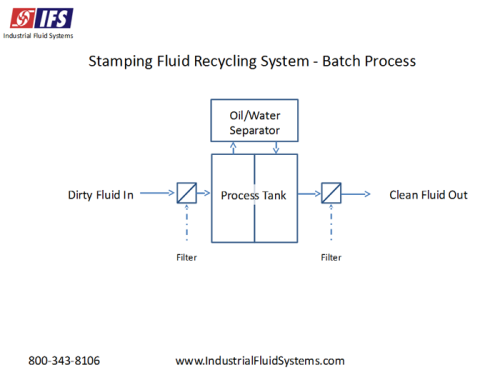

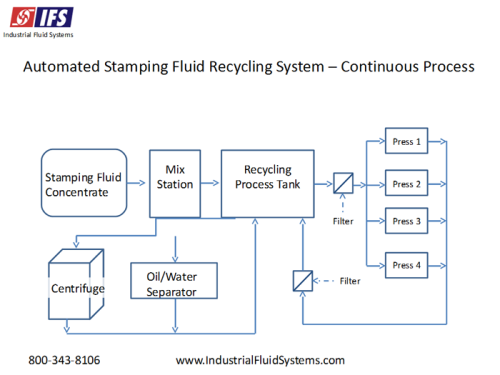

Stamping Fluids

Solids and tramp oils are the major contaminants

for stamping fluids. The processes used to remove contaminates vary based on the

fluid concentration, volume of fluid and time requirements. We have designed

both

Batch Recycling Processes

and completely automated, Continuous Stamping

Fluid Recycling Processes.

and completely automated, Continuous Stamping

Fluid Recycling Processes.

-

Low Solids/Tramp oil

Filtration is the most common method where the level of solids is low. For small metallic particles a magnetic separator can be used effectively. Solids retaining centrifuges are also an excellent choice when cost effective. Tramp oil is typically removed using oil/water separators combined with surface skimmers.

-

High Solids/Tramp oil

When there is a high level of solids and tramp oil in the fluid, self-cleaning or indexing filters are typically used. Self-cleaning centrifuges are also an effective way to remove solids from these fluids.