Oil Recycling & Purification Systems

Complete Solutions Provider, Problem

Solvers

"Processed Oil Cleanliness is Better Than Virgin Oil. Third-Party Lab

Proven."

Complete Solutions Provider, Problem Solvers

"Processed Oil Cleanliness is Better Than Virgin Oil. Third-Party Lab Proven."

Optimize Industrial Efficiency: Advanced Oil Purification Solutions

Industrial Lubricant Purification Service

- Oil Based

Cleaner Oil. Smarter Savings. Stronger Performance

- Introduction: Revolutionizing Industrial Oil Longevity

- Virgin Oil vs. Purified Oil: A Clear Difference in Quality and Performance

- Benefits of Our Oil Purification Service

- Cost Saving Projection

- Process & Oils and Fluids Best Served

- Get Started with Oil Purification

- Clean Results: Before & After Oil Purification

Revolutionizing Industrial Oil Longevit

If your facilities generate significant quantities of industrial waste oil, you can unlock substantial cost savings—up to 50% compared to purchasing new oil alone—by adopting our comprehensive recycling program.

- Oil never loses it lubricating characteristics, however with use,

oil becomes contaminated with particulates, water, and other

impurities that can degrade its quality.

- This leads to increased friction, overheating, and wear in machinery. This is where oil purification steps in as an indispensable process.

This service is brought to you by a leading manufacturer of fluid mitigation equipment, Industrial Fluid Systems (IFS), now offering a flexible service model tailored for industrial businesses seeking professional grade oil exceeding manufacturers ISO cleanliness standards.

Industries Served

- Energy

- Manufacturing

- Agriculture

- Construction

- Logistics

- Natural Resource

- Aerospace

Technology

- Cutting-edge

- Automated systems

Market Reach

- Global

Benefits of Our Oil Purification Service

-

Direct Cost Savings

Improved oil quality reduces the need for new oil purchases, delivering direct financial savings.

-

Less Purchase on Virgin Product

By reusing and purifying oil, businesses can significantly reduce the need for purchasing new virgin oil, lowering costs and supporting sustainable practices.

-

Less Spend Using Purified Oil

The cost of purified oil means fewer virgin purchases are necessary, and is generally 20~40% less than that of virgin oil, and is less subject to market volatility.

-

Less Disposal Cost

Purification minimizes waste oil generation, reducing the financial burden of disposal, every gallon purified is a savings to your bottom line.

-

Indirect Cost Savings

By reducing wear and tear on machinery through cleaner oil, companies save on operational inefficiencies and unplanned expenses.

-

Production Down Time

Clean oil extends equipment performance, minimizing unexpected breakdowns and keeping production lines running smoothly.

-

Equipment & Hardware Replacement

Prolong the lifespan of critical equipment by ensuring oil remains contaminant-free, delaying costly replacements.

-

Maintenance Labor

Eliminating breakdown repairs translates to lower maintenance costs and reduced labor hours.

Process & Oils and Fluids Best Served

- Hydraulic Oils

- Cutting Oils

- Honing Oil

- Mill Oil

- Quench Oil

- Calibration Oil

- Stamping Fluids

- Forming Fluids

- Rust Inhibitors

- Transformer Oil

- Heat Transfer Oil

- Grinding Oil

- Compressor Oil

Clean Results: Before & After Oil Purification

Practicle Count

| ISO CODE 2 | 24/24 |

| NAS 1638 Class | 12 |

| ISO CODE (3) | 25/24/24 |

| SAE AS4059 cpc | 12 |

| 4 Micron | 161018.3 |

| 6 Micron | 140174.3 |

| 14 Micron | 114094.3 |

| 21 Micron | 87925.1 |

| 38 Micron | 11348.3 |

| 70 Micron | 10.0 |

Practicle Count

| ISO CODE 2 | 16/13 |

| NAS 1638 Class | 9 |

| ISO CODE (3) | 20/16/13 |

| SAE AS4059 cpc | 10 |

| 4 Micron | 5114.9 |

| 6 Micron | 479.0 |

| 14 Micron | 52.1 |

| 21 Micron | 23.3 |

| 38 Micron | 5.3 |

| 70 Micron | 0.6 |

Virgin Oil vs. Purified Oil: A Clear Difference in Quality and Performance

Virgin AW 46

| ISO CODE (2) | 18/13 |

| NAS 1638 Class | 10 |

| ISO CODE (3) | 20/18/13 |

| SAE AS4059 cpc | 10 |

| 4 Micron | 6408.1 |

| 6 Micron | 1367.4 |

| 14 Micron | 79.7 |

| 21 Micron | 16 |

| 38 Micron | 1 |

| 70 Micron | 0.1 |

Used AW46 - Post Purification Process

| ISO CODE (2) | 12/10 |

| NAS 1638 Class | 8 |

| ISO CODE (3) | 15/12/10 |

| SAE AS4059 cpc | 7 |

| 4 Micron | 181.9 |

| 6 Micron | 35 |

| 14 Micron | 8.6 |

| 21 Micron | 5.4 |

| 38 Micron | 0.9 |

| 70 Micron | 0.0 |

Third - Party Lab Results Prove Our Process Surpasses Manufacturer Cleanliness Specifications

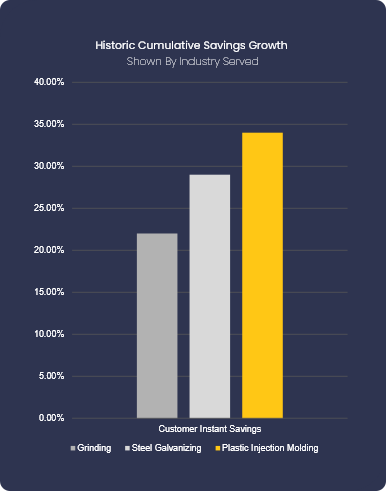

Cost Saving Projections - Based on Historic Data

- Savings Projections Leveraging historic data, our cost-saving projections demonstrate the financial impact of oil purification across various industrial operations.

- Historical Data Historical performance shows that customers have achieved an average of 30% cost savings, demonstrating the substantial financial benefits of our oil purification across industrial sectors.

- Industry Served Cumulative Yearly Cost Saving: $1.1 million

- Yearly Gallons Recycled: 354,000+

Get Started with Oil Purification

- Oil Sampling Accurate oil sampling is the first step in understanding your equipment's needs. Our experts analyze your oil to determine contamination levels, viscosity, and other critical factors, ensuring optimal purification strategies tailored to your operations. 5 Gallon Minimum.

- On-Site Oil Collection We work with your team, to establish an isolated collection process, segregating the oil for removal, and ensuring you can accumulate a preferred minimum of 3-4 IBCS (Intermediate Bulk Containers) for transport readiness.

- Logistics & Scheduling Flexible scheduling and efficient logistics are at the heart of our service. We work around and your operational hours to minimize disruption, ensuring timely pickups and deliveries to meet your production demands. The customer is welcome to arrange deliver/pick-up the oil for purification.

Onsite Estimate for your Oil Purification

| Oil Purchased Quantity (Gal) | 1000 |

| Purchased Oil Price / Gallon | $ - |

| Oil Processing Cost | $ - |

| Filter Element | $ - |

| Waste Disposal / Gallon | $ - |

| Cost of New w / Disposal | $0.00 |

| Purifed Oil Cost Delivered | $ - |

| Customer Savings | $ - |

| Projected Cost Savings | 0.00% |